“Wouldn’t it be nice if you could play Badminton properly outdoors?” I was sat enjoying a drink with George when he posed this to challenge to me. George had recently returned from holiday where he had seen a young family attempting to play badminton in the park. They struggled, they couldn’t get the equipment to work, and ultimately gave up. The main issue was that badminton shuttlecocks are not designed for the outdoor environment, they have a unique lightweight form, designed to catch the air. Their form gives a unique flight behaviour but leads to disappointing performance in wind.

Fast forward a couple of years and I received a call from George who was now working with Badminton England. “Remember that discussion? We need to make it happen!” The United Kingdom had just been awarded the 2012 London Olympic Games, and a promise had been made, a legacy of increased participation. All sports were tasked with increasing their participation numbers, but the reality was this needed to be achieved without investment in infrastructure. For Badminton this meant a radical solution had to be found, we needed to take the game outside. This was not going to be an easy task, George was requesting not only the creation of a credible solution but one that recreated the indoor experience, the shots and the moves. So began the long journey of what ultimately became the Decathlon licensed Feenixx, the first true outdoor shuttlecock.

The UK is not known for its glorious weather, we’re an island where the average summer is breezy at best, exactly what you do not want for a quality game of outdoor badminton. Products claiming to be suitable for outdoor play do exist. These typically attempt to overcome the environment by the addition of mass, or in reality are little more than novelty products. These products do not work, and players can not recreate the indoor game they enjoy in the outdoors. Just as the young family discovered, these products typically fly too fast or still get blown all over the place. The technical challenge of overcoming solving this issue although not impossible were considerable. Thankfully, I had a head start, I had been researching what makes feather shuttles behave as they do, publishing research in this area. The holy grail in badminton has always been the design of a synthetic shuttle that behaves like a premium goose feather product. Now we also had to make them also less effected by wind.

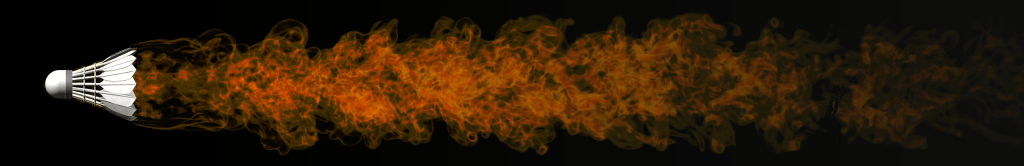

As a sports projectile shuttles are aerodynamically unique, air flows both around and through the central section of the body between the nose and the skirt. This combination of internal external flow creates a higher drag coefficient than measured in a comparable solid conical body. The movement of air between the feather vanes also creates a high rate of spin. Unfortunately, the key to designing a shuttle that is not wind affected, is the redesign and removal of this central shuttle portion that gives the unique behaviours in flight. To further complicate, any modifications also required careful consideration of the distribution of mass. Shuttles are nose heavy their centre of mass located just behind the head. This combined with their shape means that as they impact a racket and flip direction they rapidly establish a stabilised flight.

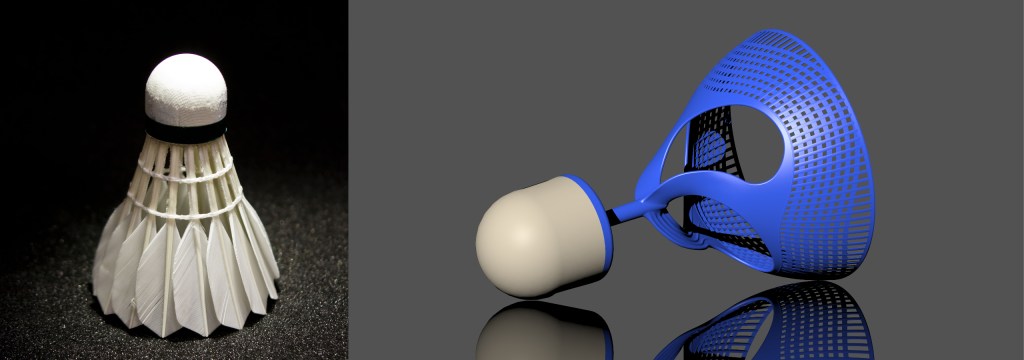

Through careful design optimisation we arrived at a form that maintained the centre of mass at a good location, whilst removing the central portion of the shuttle to reduce the influence that wind had on the flight. The solution was radical in that a single shaft was used to connect the nose to the skirt. This minimised the area of the shuttle that might “catch” the wind deviating its flight but presented a significant structural challenge. Traditional shuttles have 16 feather rachis (shafts) that connect the nose to the skirt vanes distributing the high shock loading experienced at impact. To make a single shaft design robust, a series of curved vanes were designed and optimised to connect the skirt to the shaft. These allowed the shuttle to survive the high shock loading, but also maintained spin within the design.

Having an idea is one thing, but we needed confidence that this would actually work. Through extensive prototyping and user testing cycles, the design was refined. As the project progressed the prototypes became more complex, robust and expensive. Early designs were created by hand, moving through various additive manufacture and vacuum casting approaches, until we were confident enough to open plastic injection moulds. The use of injection moulded variants permitted large scale user tests, which we undertook in collaboration with Badminton England at sites in the west midlands, and on the coast. Finally we reached the point where we had confidence that the product was suitable for demonstration to potential manufacturers.

We licensed the design to Decathlon, a global brand who specialise in the design and production of affordable quality sports equipment. They completed the industrialisation of the product, and the Feenixx shuttle was launched this summer across Asia and Europe. Its taken a long time to move from an idea over a drink to a realised product. There are many reasons behind this including financial recessions and a global pandemic. However, we are confident we have a product that is far less wind effected, and now allows users to enjoy a quality game of badminton outdoors. Hopefully the site of families playing rather than packing up badminton can now become much more common.